My office is in Manchester, in Franklin Pierce University’s graduate

school which is located in one of the renovated mill buildings located on the

Merrimack River. From the conference room there is a great view of the river and the upstream Amoskeag dam. This

is a 30-foot high, 710-foot long concrete dam that holds back the Merrimack River

at this point so that the water can be directed through the turbines at the

Amoskeag Power House located on the western bank of the Merrimack. These turbines have a combined generating

capacity of 16 MW. The photos below show my view of the dam wall and a Google

Map satellite image for an overhead view. This dam was originally commissioned

in 1924 to service the Manchester mills. While gazing at the river this week

during a meeting, I decided it was time to turn my attention to the topic of

hydro power in New Hampshire. This post is the first in a multi-part series on

this topic.

Man has utilized the power of water (hydro power) for

centuries. In the late 1700s and into the 1800s, advances in technology,

powered by running water (and eventually by steam) is what lead to the industrial

revolution. Throughout New England, textile mills were established along the

main rivers, most notably the Blackstone River that runs down through

Worchester, Massachusetts into Rhode Island and the Merrimack River that

follows a route through New Hampshire into Massachusetts. The river flow turned

water wheels and turbines which, through a system of gears, shafts, and belts, were

used to drive machinery inside the mills.

In the 1880s, water-driven turbines were combined with

electric generators to generate the first hydroelectricity, and in 1882 the world's first hydroelectric

power plant started operation on the Fox River in Appleton, Wisconsin. From

that point on, the use of hydroelectricity grew phenomenally and, in 1940, hydro generated 40% of all electricity in the

US. Since then, demand for electricity has increased ten-fold, but natural gas-,

coal-, and nuclear-fired operations were established to fill the need. Hydro

power output grew, but its share of electricity production has dropped off to

about 6 to 8% of the electricity generated in the US today.

Hydro

operations range in size from the very large 6809 MW Grand Coulee Dam in

Washington state, the 2515 MW of the Robert Moses Niagara Power Plant and the

2080 MW of the Hoover dam on the Colorado River to “hobby” projects less than 1

kW in capacity. (Remember there are 1000 kW in a MW.) There are about 1750

hydropower operations in the US: most of them are much smaller than in size than

the very large Hoover Dam operation which we usually associate with hydropower.

In fact, most hydroelectric operations

in the US are much smaller - almost 90% are less than 30

MW in size.

Hoover Dam Hydroelectric Plan

All

hydropower operations, whether private, municipal, or state-owned, are licensed

by the Federal Energy Electricity Commission (FERC) – the federal “godfather” of the electricity

business. There are 41 FERC-licensed hydro operations in NH, ranging in size

from 136 MW to 58 kW. Small projects,

such as those less than 10 MW installed on an existing dam or those of less

than 40 MW installed on a waterway used for another purpose (such as an

irrigation canal), are exempt from FERC licensing. There are 43 such exempt facilities

in NH, ranging from the 3.5 MW Gregg’s Falls operation on the Piscataquog River

in Goffstown to a 5 kW operation on Marden Brook. FERC licenses often involve

combinations of hydro operations run by a single operator on a stretch of water: for example, the three PSNH operations on the

Merrimack River are combined into one license. I also noted that the very large

Moore and Commerford hydro plants on the Connecticut River are listed by FERC

as Vermont operations. These licensing/classification artifacts can cause

confusion, especially when data on generation, as provided by the Energy

Information Agency (EIA) and used later in this post, is reviewed.

· Mini <1

MW

· Micro <100

kW

· Pico <10

kW

· Family <1

kW

To

give you a sense of what these capacities mean, it is important to remind

ourselves of the difference between power and energy. I discussed this topic in the I’ve Got the Power! blog a while ago. As a reminder, remember that electrical

energy is the ability of an electric current to do work − such as producing

motion, heat, or light. The units of electrical energy are kilowatt hours (kWh)

or megawatt hours (MWh). There are 1000 kWh in one MWh. Electrical power, on the other hand, measured

in kilowatts (kW) or megawatts (MW), is a capacity,

i.e., the rate at which energy can be

produced from a generator. Large generators, which can produce more energy per

unit of time, naturally have larger capacity or power ratings.

The confusion between power and energy often

stems from the similarity of the units: kilowatt hours or megawatt hours are

energy units, and kilowatts or megawatts are power units. However, it is important

to understand that even though the units seem similar, there is a world of

difference between them. This difference stems from the simple mathematical

relationship between energy and power;

Energy = Power x

time.

I

find it is always useful to understand these relationships from a homeowner’s

point of view. Consider that an average US household uses 11,000 kWh per year of

electricity (~900 kWh per month). If you had to generate that electricity

yourself and you were going to do it over 24 hours a day for 365 days per year,

you would need generator with a power rating of 1.3 kW.

The

calculation would be done as follows:

Energy = Power x time

Power = Energy / time

Power = 11,000 kWh/(365 days x 24 hours/day) = 1.3 kW.

Of

course, this calculation is based on a daily average, but our daily electricity

use is actually rather “lumpy”: there is

a first peak in the morning as we turn on the lights, make coffee, heat up the

house, and take hot showers, followed by a second and larger peak in the late

afternoon/evening when we are making dinner, watching TV, doing the laundry, turning

on the electric blanket, reading this blog, etc. If you were to actually buy a

generator, you would want a unit that has a capacity of more than the average

1.3 kW so that it could handle the peaks in usage. This is why backup

generators for homes often have sizes of the order of 5 kW to 15 kW. But I

digress somewhat (I may come back to the topic of home generators in a future

post)….

The

second classification of hydro plants is by type of operation. The three main

types are:

- Reservoir or Pond-and-Release Operations: We most commonly

associate these with hydropower and they involve large concrete dams holding

back enormous reservoirs of water with the power plant at the base, as shown in

the Hoover Dam picture above. The reservoir provides for a great deal of

storage and steady power generation even during the dry season. These operations

usually involve the upstream flooding of large tracts of land and significantly

impact downstream water flows. The water level in the reservoir can also

fluctuate greatly, depending on the incoming water flows and the discharges

through the power station.

- Run-of-River Operations: These hydroelectric plants depend on

the natural drop in the river elevation. A portion of the upstream river flow is

sometimes diverted through a large pipe (called a penstock) to a downstream

generator plant, after which the water flow is reintroduced into the river (see

the figure below). These operations often have dams at the upstream location to

provide the water diversion point but their storage capacity, called pondage,

is limited and, as such, these operations are more subject to the vagaries of seasonal

precipitation and natural river flows. With limited storage, the reservoir

level tends to remain fairly constant – excess river flow simply spills over

the top of the dam. Electricity production can therefore vary substantially

over time. Because these operations don’t involve large amounts of storage or flooding

of large acreages of land, they tend to viewed as more environmentally friendly

or “greener” than the larger reservoir operations.

- Pumped Storage: These operations involve pumping water from a

river uphill to a reservoir at a higher elevation during low electricity demand

and low cost periods. When electricity demand increases and prices are high,

these operations then run in reverse and the water in the reservoir is drained

through a turbine back into the river, generating electricity in the process.

There are a three of these operations in New England with a combined

capacity of 1696 MW.

In

NH, we do not have any pumped storage operations but we have reservoir and run-of-river

operations. Data from the EIA indicates

that there are 92 hydro generators in NH with a combined name-plate capacity of

446 MW and a total winter capacity of 511 MW. The ten largest NH hydroelectric operations

are listed below. The Moore and

Comerford dams, located on the Connecticut River which runs between New

Hampshire and Vermont, are the largest hydro operations in all of New England.

All operations listed are individual dams, except for the Great Lake Hydro-owned

operation on the Androscoggin River in the Berlin area which is a series of

different dams and 21 generating facilities. The largest PSNH-owned operation

in NH (and the one that distracts me during meetings) is the Amoskeag dam on the Merrimack River.

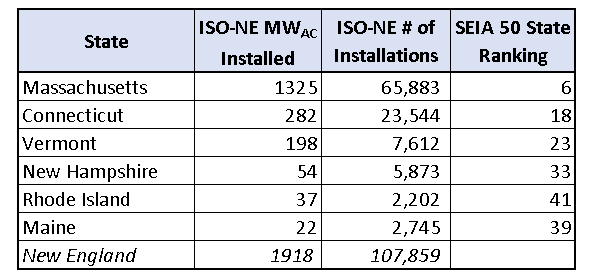

As a wrap-up for this post, I thought a comparison with

other New England states would be interesting. The table below lists total

electricity production capacity (the power of the generator) and hydro capacity

by state for 2012, as well as total production of electricity and

hydroelectricity. The data include conventional hydro only and excludes pumped

storage operations. We can see that Maine is the “hydro powerhouse” of the New

England region, with the largest capacity, followed by NH. The upper New

England states, New Hampshire, Vermont, and Maine provide the bulk of the region’s hydro

generation capacity.

I note with interest that, even though Maine total hydro

capacity was only 17% of its total generating capacity, 26% of their

electricity output for 2012 was generated from hydro. This means that their

hydro plants worked very hard in 2012, which is indicated by the highest

capacity factor for their combined hydro plants. (Recall from I’ve

Got the Power! that capacity factor is the ratio, expressed as a

percentage, of the actual electricity output from a generator over a year

compared to the theoretical output if the unit operated 24 hours/day 365 days

per year.) The comparative numbers for NH are quite different. In orange I have

highlighted that hydro represented 10% of NH generating capacity but, in 2012,

it was, surprisingly, only responsible for 7% of the NH total electricity

output. The capacity factor of all NH’s hydro plants, in yellow, was therefore an

extraordinary low 33%.

This anomaly is quite striking and some follow-up research

is warranted. It is clear that hydro power is intriguing topic and I plan to

continue my explorations in future posts. Now, when I gaze out the windows at

the Merrimack River and the upstream Amoskeag dam during faculty meetings, my

colleagues can be assured that my distraction is not idle daydreaming; instead

I will be thinking of river flows, generating plants, and capacity factors!

Until next time, remember to turn off the lights when you

leave the room.

Mike

Mooiman

Franklin

Pierce University

(*Down by the Water – A great tune by

one of my favorite indie groups, The Decemberists. These guys are great song

writers and I always look forward to their new releases. Here they are from Austin

City Limits – the best music show on TV. Enjoy Down by the Water.)